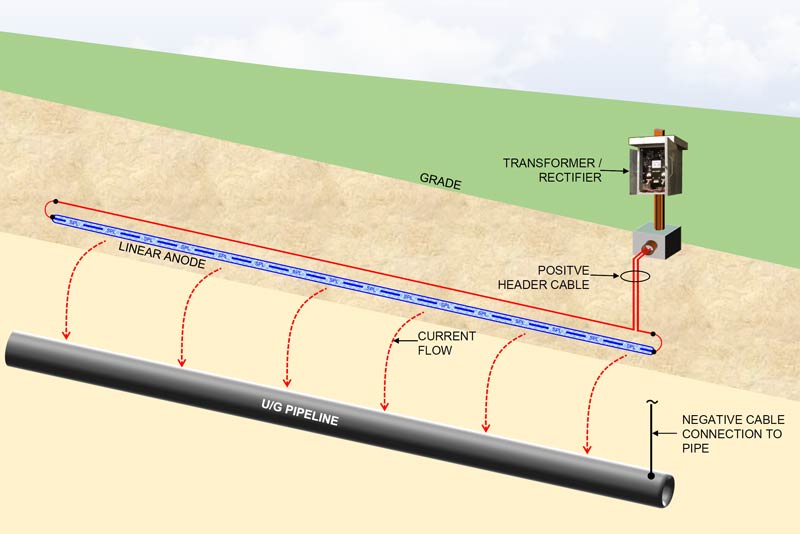

A common cathodic protection system approach is the use of a shallow horizontal anode bed. Deep anode ground bed systems have been utilized for decades to distribute cathodic protection current to protect pipelines storage tank bottoms well casings and other buried structures.

Search for jobs related to Cathodic protection ground bed design or hire on the worlds largest freelancing marketplace with 20m jobs.

. All that is needed is a deep hole for the anodes. Electrical Isolation Insulating devices must be installed on the steel pipe so as to facilitate electrical isolation. These anodes should be buried deep in the ground a certain distance away from the structure it protects.

Once the groundbed becomes operative the steel casing will be consumed. A cathodic protection program study indicated that conventional ground bed designs have three major disadvantages. Its free to sign up and bid on jobs.

CURRENT DEMAND Initial Mean Final CP. Log in Register. Total annual cost means the sum of the costs of power maintenance and charges against the amount of capital invested.

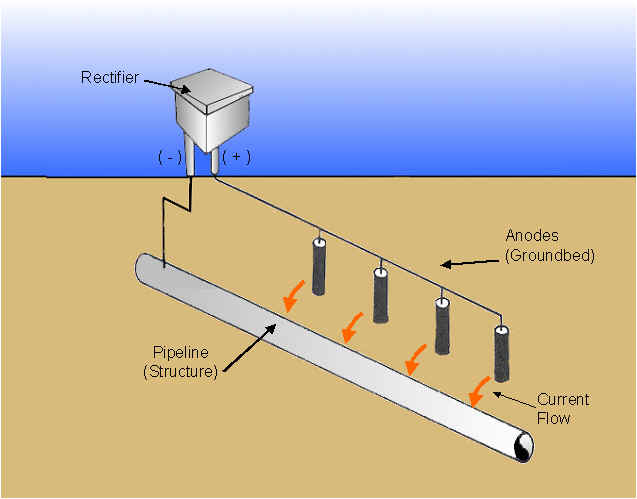

CATHODIC PROTECTION DESIGN STRUCTURE Metal Design Life Dimensions Coatings Other COST AND IMPLEMENTATION LOCATION Environmental Conditions Other Structures ANODE AND HARDWARE SELECTION Current Output Design Life Placement CP. Poor current distribution occurs along the casing string. The two types of CP systems are galvanic anode and impressed current.

Design Principles The ideal design for a cathodic protection system is the one which will provide the desired degree of protection at the minimum total annual cost over the projected life of the protected structure. One important element in designing a cathodic protection system is the structures physical dimensions for example length width height and diameter. A cathodic protection program study indicated that conventional ground bed designs have three major disadvantages.

These data are used to calculate the surface area to be protected. The remaining space is then filled with carbonaceous material. Page 2 of 8.

Cathodic protection is a method used to reduce steel oxidation through an electrochemical process. A groundbed is an electrode array that is installed beneath the ground to give off a path with low resistance to ground. Cathodic protection levels must be controlled so as not to damage coatings.

A new CP ground-bed design compared with traditional design 27 14 anode rods dispersed in two parallel groups are calculated firstly. Plant and facility environments however are not simple applications. Cathodic protection is used to protect buried or submerged pipelines bridges and large steel structures from corrosion breakdown and rust when an electrolyte like water with salt and minerals is present.

When connected in a circuit the cathodic protection current flows from the anode more negative to the structure less negative. A groundbed cathodic protection system is a low-cost and highly effective option since various components like tanks pipes fuel pumps wirings and others need not be interrupted. Cathodic Protection Provide a level of cathodic protection for the entire length of the underground structure.

Several anodes attached together with a rope are placed inside the casing. The cathodic protection system has. The electrolyte serves as a conduit for the electron.

When properly applied galvanic anodes also called sacrificial anodes can protect underground steel marine. Cathodic protection CP CP design CP survey DCVG anodes offshore CP survey onshore CP survey CP survey cathodic protection transformer rectifier ground bed anodes anodes CIPS COPS corrosion stray current galvanic impressed current Perth Australia Western Australia WA. The results show that this design can not meet the grounding resistance requirement.

REVIEWED EXECUTED BY. A new CP ground-bed design compared with traditional design 27 14 anode rods dispersed in two parallel groups are calculated firstly. Ground Bed Design and Installation.

GROUND BED GB DESIGN. Poor current distribution occurs along. The conventional rectifier-ground bed system involves burying numerous non-sacrificial anodes about 100 ft from the well head and some 10- to 20-ft deep.

Plants have congested underground piping. The results show that this design cannot meet the grounding resistance requirement. 212 Drawing of structure to be protected.

For many underground applications such as pipelines cathodic protection system design is relatively straightforward. Get in touch United by our common purpose to unlock solutions to the worlds most. We can provide unique and innovative design and installation techniques to aid in.

The design and installation practices of deep well anode systems have a significant impact on the life and performance of the structure. Galvanic anode CP systems provide cathodic current by galvanic. A basic design incorporates the use of a steel casing to prevent the collapse of the drilled hole.

CATHODIC PROTECTION CALCULATION. Design of Deep Anode Ground Bed for Cathodic Protection of Oil Pipelines Using Pv Modules At Port Harcourt Nigeria 1Mee AU 2Ahmed AD 3Udounwa AE. Another 4 designs with anode rods arranged as 26 28 29 36 are calculated respectively.

And 2Wansah JF 1Department of Physics and Astronomy University of Nigeria Nsukka 2Department of Physics Madibbo Adama University of Technology Yola. TYPE Impressed Current Sacrificial Anode CP. CAL Contract Job No.

Another 4 designs with anode rods arranged as 26 28 29 36 are calculated respectively. Cathodic protection is a means of reducing corrosion of a metal by artificially causing direct current to flow from external anodes through the electrolyte soil or water and onto the structure to be protected. Cathodic protection when applied properly is an effective means to prevent corrosion of underground plant piping.

1 Owner Job No.

Shallow Horizontal Anode Bed Design With Linear Anodes Matcor Inc

Cathodic Protection Systems And The Nec Ec M

Cathodic Protection Definition Working Principles Types Design Advantages Applications Pdf What Is Piping

Anode Installation An Overview Sciencedirect Topics

0 komentar

Posting Komentar